12 May D2 Steel : Everything you need to know

Discover the exceptional properties of D2 steel, renowned for its remarkable wear resistance and hardness. From composition to applications, advantages, and heat treatment, this guide covers everything you need to know about maximizing the potential of D2 steel.Explore the superior wear resistance and toughness of D2 steel. Learn about its composition, applications, and heat treatment in this comprehensive guide.

When it comes to high-performance steel, D2 steel stands out as a top contender in tool and die making, knife crafting, and industrial applications. This guide delves into D2 steel, from its composition and properties to applications, advantages, and disadvantages.

Definition and Composition

D2 steel, a high-carbon, high-chromium tool steel, is revered for its exceptional wear resistance and hardness. Composed primarily of carbon, chromium, vanadium, molybdenum, and manganese, D2 steel exhibits a robust molecular structure ideal for demanding applications.

Properties and Characteristics

D2 steel boasts:

- High wear resistance, ensuring prolonged tool life even under extreme conditions.

- Balanced hardness and toughness, providing durability and resilience.

- Excellent corrosion resistance, safeguarding against rust in harsh environments.

Applications

D2 steel finds use in:

- Tool and Die Making: Ideal for cutting tools, dies, and punches requiring sharpness and durability.

- Knife Making: Renowned for superior edge retention and toughness.

- Industrial Uses: Indispensable in various industrial applications for precision and reliability.

Advantages

- High Wear Resistance: Ensures extended tool life and minimal maintenance.

- Balanced Hardness and Toughness: Withstands heavy loads without compromising edge retention.

- Corrosion Resistance: Enhances longevity in challenging environments.

Disadvantages

- Difficulty in Machining: Requires specialized equipment and expertise.

- Proneness to Chipping: Excessive impact or misuse can lead to chipping.

Heat Treatment

Optimize performance through:

- Annealing: Relieves internal stresses and improves machinability.

- Hardening: Achieves maximum hardness through precise heating and quenching.

- Tempering: Enhances toughness and reduces brittleness.

Maintenance and Care

Ensure longevity by:

- Keeping tools clean and dry.

- Regularly sharpening knives.

- Avoiding excessive force or impact.

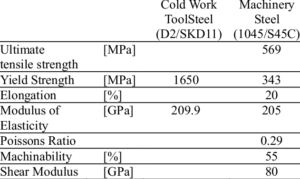

Comparison with Other Steel Types

- High-speed steel (HSS)

- Stainless steel

- Tool steels like A2 and O1

Conclusion

D2 steel epitomizes excellence in high-performance steel, offering unparalleled wear resistance, hardness, and corrosion resistance. Its versatility and reliability make it a preferred choice across various industries. With proper care, D2 steel products deliver superior performance in demanding environments.

Adding Depth to D2 Steel: Industrial Applications

In the industrial realm, where precision and durability are paramount, D2 steel emerges as a star player. Its exceptional properties make it indispensable for a wide array of applications.

Industrial Blades and Shear Blades

D2 steel’s high wear resistance and toughness make it an ideal choice for industrial blades used in cutting, shearing, and slicing applications. From paper mills to metal fabrication plants, D2 steel blades ensure precise and efficient cutting operations.

Cold Heading Tools and Forming Dies

In the manufacturing of fasteners, rivets, and other formed metal components, D2 steel finds extensive use in cold heading tools and forming dies. Its ability to maintain sharpness and withstand high-pressure forming processes makes it a preferred material for ensuring consistent and accurate part production.

Stamping and Punching Operations

D2 steel punches and stamping dies are essential components in various stamping and punching operations across industries such as automotive, aerospace, and electronics. The hardness and wear resistance of D2 steel enable these tools to endure the repetitive stress and abrasion inherent in such operations, ensuring precise and reliable part production.

Plastic Molding and Extrusion

In plastic molding and extrusion processes, where high temperatures and abrasive materials are commonplace, D2 steel plays a vital role in the production of molds, dies, and extrusion tooling. Its excellent thermal conductivity and wear resistance make it well-suited for withstanding the rigors of these processes, resulting in high-quality finished products with tight tolerances.

The Future of D2 Steel in Industry

As industries continue to push the boundaries of performance and efficiency, materials scientists are constantly exploring new avenues to enhance the properties of D2 steel and other high-performance alloys. Recent innovations in metallurgy, heat treatment techniques, and alloy design have led to the development of advanced D2 steel variants with improved toughness, wear resistance, and machinability.

In conclusion, the continued advancement of D2 steel and its derivatives holds great promise for the future of materials science and engineering. Through innovative technologies, optimized processes, and collaborative research efforts, D2 steel is poised to remain a cornerstone of high-performance materials, driving innovation and progress across a wide range of industries for years to come.

No Comments